The modern warehouse is a marvel of organisation, efficiency, and safety. Today, when you walk into a warehouse, you’re greeted by well-defined pathways, clearly marked zones, and robust safety barriers separating workers from heavy machinery. It’s easy to take these safety measures for granted, but it’s important to remember that this was not always the case. To truly appreciate the evolution of warehouse safety, we need to step back in time to an era when safety barriers and machine guards were non-existent, and the industrial workspace was far more hazardous.

The Industrial Revolution & the Birth of the Modern Warehouse

The late 19th and early 20th centuries marked a period of rapid industrialisation. Factories and warehouses sprang up across the UK and Europe, becoming the backbone of a burgeoning economy. These warehouses were designed with one primary goal: to store and move goods as efficiently as possible. As industries grew, so did the size of warehouses, and with them, the need for machinery capable of handling the heavy lifting.

During this period, warehouses were bustling with activity. Workers manually loaded and unloaded goods, while machines—rudimentary by today’s standards—handled tasks that were too arduous for human labour alone. Forklifts, conveyors, and other mechanised systems became increasingly common, revolutionising the way goods were stored and transported.

A Chaotic & Dangerous Environment

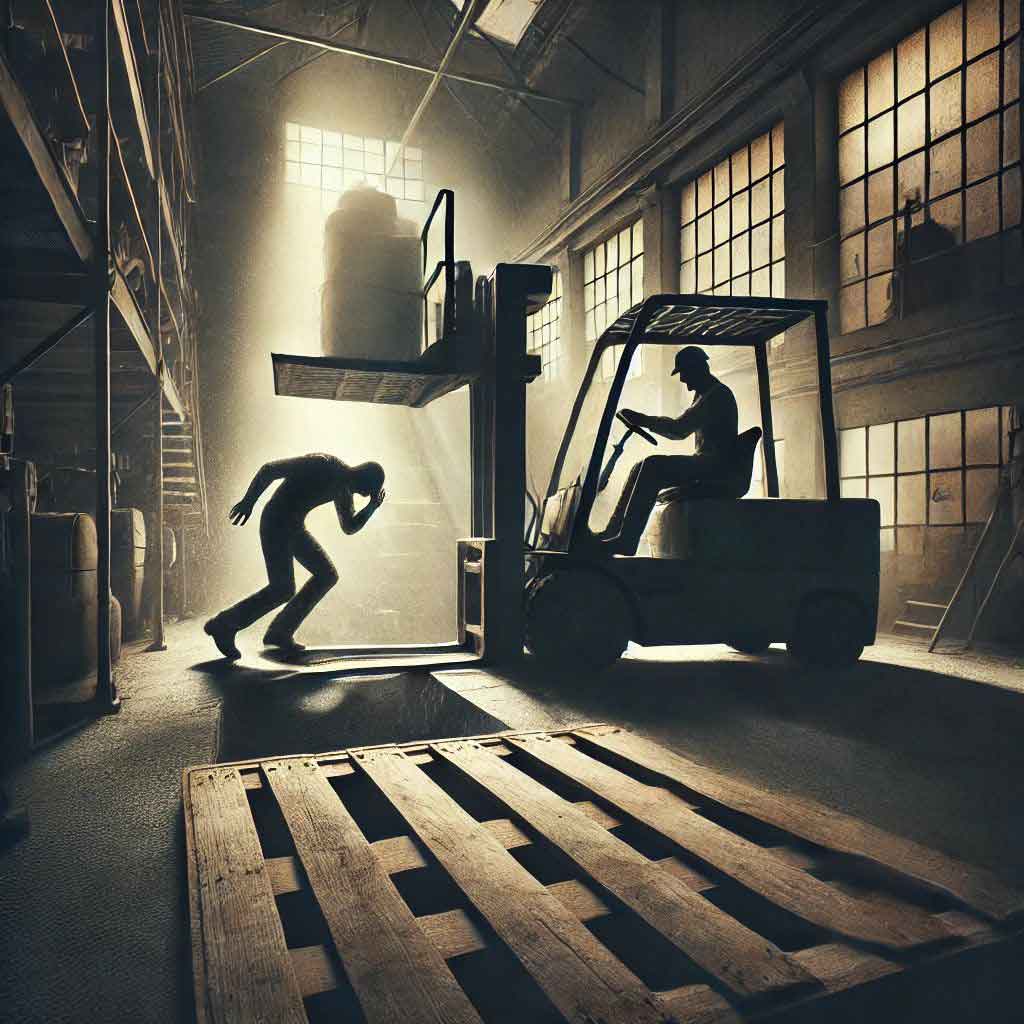

However, this early embrace of mechanisation came with a significant downside: safety was not a priority. The primary focus was on productivity and throughput, with little thought given to the potential risks posed by these new machines. Warehouses were often dimly lit, poorly ventilated, and crowded with both people and equipment. The noise levels were deafening, with the constant clatter of machinery creating an environment that was not only stressful but also hazardous.

In these early warehouses, there were no safety barriers or defined walkways to separate workers from machinery. Heavy equipment moved freely throughout the space, often with little regard for the people who worked alongside it. The absence of safety protocols meant that workers were at constant risk of injury. Without barriers to protect them, the danger of being struck by a moving vehicle, caught in machinery, or even crushed by falling loads was ever-present.

The Human Cost: Accidents & Injuries

The lack of safety measures in these early warehouses led to a high incidence of workplace accidents. Injuries were a common occurrence, ranging from minor cuts and bruises to severe, life-threatening incidents. The psychological impact on workers was significant. Many lived in constant fear of the machinery they worked alongside, knowing that a single misstep could result in a catastrophic injury.

The human cost was immense. Workers who were injured often faced long recoveries, with many unable to return to their jobs. In some cases, injuries resulted in permanent disabilities, robbing workers of their livelihoods. The financial burden on families was heavy, with many struggling to make ends meet after a breadwinner was injured.

The consequences for employers were also profound. High accident rates led to decreased productivity, as injured workers had to be replaced or shifts reorganised. The absence of injured workers also meant that others had to take on additional responsibilities, often leading to overwork and fatigue, further increasing the risk of accidents. Additionally, employers faced legal challenges as injured workers or their families sought compensation for accidents that could have been prevented with better safety measures.

The Awakening: Early Efforts to Improve Safety

As the toll of workplace accidents became impossible to ignore, a gradual shift in thinking began to take place. By the mid-20th century, the importance of workplace safety was becoming increasingly recognised. The introduction of the Health and Safety at Work Act in 1974 in the UK was a significant turning point. This legislation made it a legal requirement for employers to ensure, as far as reasonably practicable, the health, safety, and welfare of their employees.

This period saw the beginning of a transformation in warehouse safety. Companies started to introduce basic safety measures, such as better lighting, clearer signage, and more defined walkways. However, it was the introduction of safety barriers that truly revolutionised the industry.

The Game Changer: The Advent of Safety Barriers

Safety barriers, when they were first introduced, were a revelation. They provided a physical and visual separation between workers and machinery, dramatically reducing the risk of accidents. Barriers were installed to create designated pathways for pedestrians, ensuring that workers could move around the warehouse without coming into contact with heavy machinery. They also helped to protect expensive equipment from damage, reducing downtime and maintenance costs.

Over time, safety barriers evolved. Early barriers were simple structures, often made of wood or metal. Today, they are engineered to absorb impact, made from durable materials that can withstand the rigours of a busy warehouse environment. Modern barriers are also designed to be modular, allowing them to be easily installed, relocated, or expanded as the needs of the warehouse change.

The impact of safety barriers cannot be overstated. They have transformed warehouses from hazardous, chaotic spaces into organised, safe environments where workers can focus on their tasks without the constant fear of injury. The introduction of barriers also helped to foster a culture of safety within the workplace, encouraging workers and management alike to prioritise health and safety in all aspects of their operations.

The Legacy of Progress: A Safer Future

Reflecting on the past, it’s clear how far we’ve come in the realm of warehouse safety. The dark days of the early industrial era, when workers were left to fend for themselves in dangerous conditions, have given way to a modern approach that prioritises safety, efficiency, and worker well-being. Safety barriers, once a novel concept, are now a standard feature in warehouses around the world, a testament to the progress that has been made.

At Billington Safety Systems, we are proud to be part of this ongoing evolution. Our mission is to continue advancing safety in the workplace by providing innovative, reliable safety solutions that protect workers and improve operational efficiency. We believe that every worker deserves to return home safely at the end of the day, and we are committed to making that a reality.

As we look to the future, we will continue to build on the lessons of the past, ensuring that warehouses remain safe, efficient, and productive environments. The introduction of safety barriers was a pivotal moment in the history of industrial safety, and at Billington Safety Systems, we are dedicated to pushing the boundaries of what is possible, creating even safer workplaces for generations to come.